When my husband announced with classic hunter-gather pride that he had secured a classic bicycle frame for me, I responded with classic homemaker angst, "What color will I paint it?" This was in March 2006.

Of course we are not classics in the behavioral sense. He is not much of a hunter and I am certainly not a homemaker. Yet when the frame arrived, the question remained: What color, indeed, would it be painted? Of course I could chrome the frame. Something I was attracted to since the release of the 2005 Bianchi Pista. But that seemed impossibly mysterious and complex.

So, the choices were two. Be true to the manufacturer's intent, creating a mild anachronism, or choosing a color I liked, creating a modern classic. To help us make the decision, I looked at the frame and its origins for clues.

The frame, a $50 eBay acquisition, arrived (via $30 shipping) badge-less, re-painted, and, in places, scratched down to darkening bare metal. The seller, a respectable eBay citizen, could only identify it as an early 80's era Miyata. As it turned out, it could have been any one of a handful of frames built by Miyata but badged as either Miyata or Univega. Fortunately, I didn't care for any of the specified paint schemes.

The frame, a $50 eBay acquisition, arrived (via $30 shipping) badge-less, re-painted, and, in places, scratched down to darkening bare metal. The seller, a respectable eBay citizen, could only identify it as an early 80's era Miyata. As it turned out, it could have been any one of a handful of frames built by Miyata but badged as either Miyata or Univega. Fortunately, I didn't care for any of the specified paint schemes.

That left me free to dream of a finish of my own liking. So, once again I turned to my most trusted bike-style advisor, the internet. I spent hours ogling or hissing at bikes all over the net. Rattle-canned, clear-coated, powder-coated, covered with postage stamps, and factory-painted chrome (hmm). I even saw a copper plated bike (yikes!).

By May, I had narrowed things down to powder coat paint, because of its durability, in either white, taupe, or forest green. Dutifully, I built a list of cyclist-recommend shops and interviewed each. I checked them for price and turnaround time, and I even made a site visit. Yet all the while, chrome played in my mind....I would never be content until I ruled it out.

After my last visit to a painter the following month, I dropped by an auto body shop who referred me to the only nearby chrome plating shop. I telephoned. Yes, they've plated bicycle frames, and I could come with the frame for a quote. Excitedly I dashed over and met with their estimator. "Two hundred seventy five dollars," he proclaimed after hemming and hawing, sizing me up more than the frame. Yeah, right! Stung more by his prejudice than his quote, I wordlessly picked up my frame. He could size up my butt on my way out the door, as far as I was concerned.

That evening, I confessed my silly desires to Rick. "Not silly at all," He said. "A lot of older bikes are chrome under their paint. In fact they have been chroming bicycles since at least the 1940s. Tell you what, let me find a plater for you. I've been in the business before (he had been a motorcycle mechanic long ago), and I know what to look for."

That evening, I confessed my silly desires to Rick. "Not silly at all," He said. "A lot of older bikes are chrome under their paint. In fact they have been chroming bicycles since at least the 1940s. Tell you what, let me find a plater for you. I've been in the business before (he had been a motorcycle mechanic long ago), and I know what to look for."

In short order Rick had found a plater with bicycle frame experience who would do the job for under $200. The shop was called Chrome Nickel Plating, and he found it in the yellow pages under Chrome Nickel Plating. (He always makes it look so easy!)

Could it be true--a chrome frame? A few weeks later, we went for a visit and a quote. The shop was located in Lynwood, near Alameda Street on Martin Luther King Jr. Boulevard. In the midst of massive warehouses and industrial production, Chrome Nickel Plating was in a comparatively small one-story building.

It was late July and hot. As we walked passed the roll-up door and into the facility, the 48" industrial-strength floor fan blew uselessly inward, barely stirring the acrid-sweet smell of heated metal. There was no lobby or waiting room. This was where it happened--the production line. It occurred to me that Chrome Nickel Plating catered not to the owners of $30K motorcycles, but to those who build them. The shop was no nonsense, dingy-looking, and aging, but clean.

At one end, men stood at the controls, maneuvering large frames as they glided over a long sequence of massive vats. The frames held swaying beneath them various things like automobile bumpers and racks and rows of Harley-Davidson headers.

To my left, women were doggedly working, cleaning and wrapping the larger orders, I assume. To my right was a rack of small but impossibly shiny parts: the emblem of a Dodge Dart, some handles and fasteners, and some short L-shaped rods. Hanging there, the collection reminded me of dew on a spider's web.

Rick had stepped aside with the serious-faced Small Parts Manager and was discussing the nuts-and-bolds (so to speak) of our request.

I looked over at the vats again, and watched in fascination as, at last, metal parts would come to the end of the line and the operator would jump to inspect his work. Once, an operator called over another man, and both looked disapprovingly at the job, coming to a dissatisfied conclusion: the frame and all its parts were foisted away to the beginning of the process, no doubt to be stripped and redone.

Rick came over to me smiling. "Miguel said it won't be a problem. He will charge us about $160 plus tax. Cash. That includes the forks, and he needs a couple of weeks to do it. I suppose he has to wait for enough similarly-sized parts to justify going through the whole process."

The whole process? Something was stirring in my brain. Chrome Nickel Plating. A multi-step process. "Rick, is nickel something separate or is it part of the process?"

"It's part of the process. It goes into a copper bath, then nickel, then chromium."

The copper plated bicycle I saw online, was it just the first step in the process? Then nickel.... "Honey, what about nickel? Could I get my bike nickel plated if I wanted to....maybe?

"Sure, you just skip the final chromium step," he said. "In fact, nickel plating bike frames goes back to the early days of chrome plating. I love nickel plating! Let me ask if he will do it."

It seems that, a) everything goes back to the early days, and b) my husband will never cease to amaze me.

As it turned out, nickel plating was no problem, and best of all, no price difference. (Should it have been a little less expensive because we are skipping a step? Maybe.) We'd bring the frame back stripped of all parts, including headset and bottom bracket. No need to plug the holes, Miguel would take care of it. And on August 12, 2005, exactly two weeks (practically to the hour!) after we dropped it off we were back. Miguel was a little surprised at our timeliness, I think, because the frame was not in the holding area and wasn't plastic wrapped like the other finished parts.

Quickly he fetched it and wrapped it up. We paid him and I took ownership of a sparkling bicycle frame and fork. I was in awe. Rick was in awe. It was far more beautiful than either of us would have guessed.

Putting the beat-up old parts back on my gleaming frame seemed irresponsible. So, while I saved-up for a better bottom bracket and headset, it held a place of honor in our living room. I cared little, stylistically, about components except for the headset. For that I had a clear desire: Chris King. I ordered, to my mind, the perfect color complement to a nickel-plated frame, the 2006 Special Edition Chris King headset. I call the color "CSR pink"--for Corporate Social Responsibility. (See their website and learn why it applies.)

Putting the beat-up old parts back on my gleaming frame seemed irresponsible. So, while I saved-up for a better bottom bracket and headset, it held a place of honor in our living room. I cared little, stylistically, about components except for the headset. For that I had a clear desire: Chris King. I ordered, to my mind, the perfect color complement to a nickel-plated frame, the 2006 Special Edition Chris King headset. I call the color "CSR pink"--for Corporate Social Responsibility. (See their website and learn why it applies.)

As I waited for it to arrive I decided to try out the fork into the head tube for the first time. It would not go in. Rick tried, and it wouldn't go in. My heart sank as he brought the fork up for closer inspection. "Flash." He said pointing. Peering from around his shoulder I looked closely. There, at the transition of bare to shiny metal, one inch below the threads, was a wreath of nickel beads. Of course there would be flash. Yes, Miguel should have removed it during polishing. Probably would have if he had a chance. Yes, we should have been more diligent in our inspection. But we were so excited about how beautiful it came out.

All the same, hindsight wouldn't remove the flash, but a good metal file and some elbow grease would. So, undaunted, we bought a file and I went to work like a Civil War era surgeon. Feebah, feebah, feebah.... "Hold still." Feebah, freebah.... "Rick, hold him steady!"

All the same, hindsight wouldn't remove the flash, but a good metal file and some elbow grease would. So, undaunted, we bought a file and I went to work like a Civil War era surgeon. Feebah, feebah, feebah.... "Hold still." Feebah, freebah.... "Rick, hold him steady!"

Soon the fork fit perfectly, and neither it nor I was any worse for wear and tear.

But now I was feeling antsy. Surely that would be the last barrier before attaching the components and riding into the sunset. It was six months since the frame arrived that early Spring morning, and it was getting onto Autumn now.

So when the headset arrived, I wasted no time getting to nearby bike shop for installation. (Chris King headsets require a special tool for installation.) The proprietor, whom Rick has known for two decades, and whose shop is always backlogged with work, estimated two days. So close to finish now!

I went home and passed the time, like a little girl on her birthday, assessing my collection of new toys: The old, nameless headset and bottom bracket are in a bits box somewhere in our garage, destined to be forgotten. Over the months I collected, with Rick's help, wheels (hubs/skewers/rims/spokes and tires), Nitto Randonneur bars, cassette, derailleurs, and bar-end shifters. Also, I've got a set of panniers, saddle and seat post, pedals, toe clips (replete with all-important yellow leather ALE straps), a chain, and some bar tape.

I went home and passed the time, like a little girl on her birthday, assessing my collection of new toys: The old, nameless headset and bottom bracket are in a bits box somewhere in our garage, destined to be forgotten. Over the months I collected, with Rick's help, wheels (hubs/skewers/rims/spokes and tires), Nitto Randonneur bars, cassette, derailleurs, and bar-end shifters. Also, I've got a set of panniers, saddle and seat post, pedals, toe clips (replete with all-important yellow leather ALE straps), a chain, and some bar tape.

My Shimano XD600 crankset and a bottom bracket were in transit, and a set of side-pull brakes was pending from Kogswell. Lastly, a pair of Shimano brake levers and a stem were on hold at the bike shop. (For those of you who may be curious as to the details, I'll provide a more complete parts description in a separate submission.)

At my appointed time I returned to the bike shop full of anticipation. But when I saw the proprietor's face I stopped. Indeed, bad news. The headset didn't fit. He carefully explained to me that the fork crown was too thick for the crown race to fit. It wasn't the headset, it was the crown race, which was somehow not the standard size.

The headset didn't fit! What madness was this? Oh, the iniquity! Who was I supposed to be, Job? These thoughts and worse fought for release. I said nothing, but Steve knew my mind.

"The good news is that there is a good chance it can be fixed." He knew a master machinist who might be able to resize the crown. A quick call and, knowing my anxious state, he arranged for a Saturday (same day) appointment.

Rick and I arrived that afternoon at the West Los Angeles address and were met by a man with an open face, friendly eyes, and the careful air of a perfectionist. This was Mr. Steve Thompson, our machinist and the shop's proprietor.

Steve's business, T.B.M. Manufacturing Corporation, started as a commercial bagel-making-equipment manufacturer. Still sought for this work, it has since branched out to include all other types of machining.

After chatting bikes for a while (he has a turn of the millennium Gary Fisher mountain bike), we turned to business. He examined the forks and listened to our plight. He asked a few pointed questions of my husband and decided on an approach. But first, a scolding. "You should have had this machined before it was plated," he said. To shave it away now is to risk it peeling. Of course he was right. it was our oversight. Yet shave it away he must.

He looked closer and added, "The top of the fork crown isn't perfectly circular either. Look" (I didn't see anything but Rick nodded sagely.) The consensus was that the person who originally milled this piece had done a poor job. Steve shook his head, now galvanized to the task. T.B.M. Manufacturing would make things right, he seemed to conclude. And for the next twenty minutes he oh-so-carefully shaved mil after mil of steel away, checking as he went.

He looked closer and added, "The top of the fork crown isn't perfectly circular either. Look" (I didn't see anything but Rick nodded sagely.) The consensus was that the person who originally milled this piece had done a poor job. Steve shook his head, now galvanized to the task. T.B.M. Manufacturing would make things right, he seemed to conclude. And for the next twenty minutes he oh-so-carefully shaved mil after mil of steel away, checking as he went.

My perfected forks did not come without a price. Electroplating is self-sealing at the coating's edges. Because Steve had to cut into the finish, there now is a risk of peeling that can progress down the length of the finish. My case has two mitigating factors in my favor. First, the crown race may help pin down the finish. Second, Steve believes that the finish is of high enough quality that it will resist peeling better than others. Only time will tell.

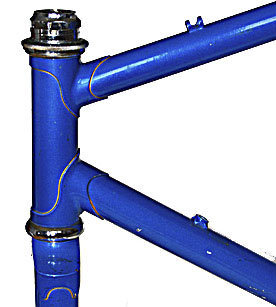

It is five days after Steve Thompson re-milled the fork crown, now. As I write this, my Miyata is again in our living room, perfected forks firmly attached by beautiful headset. Soon, my crankset and brakes will arrive, and we will begin the process of assembly.

My fifty dollar frame, free of any parts, has ballooned in price by five times, to nearly $250. Through the judicious selection of parts, chosen based on casual price/quality/appearance criteria, the finished bicycle should come together for under $600. That's one hundred dollars a month, or a mere twenty five dollars a week. Not bad when you look at it that way.

And to me, the intervening months have been an adventure. I have learned so much from the many online enthusiasts and experts: i-BOB, cyclofiend, fixedgeargallery, and many, many others.

Moreover, every bicycle I've ever owned had come to me fully assembled. Painters, platers, machinists....few of us, men or women, ever get to meet the skilled crafters who make the machines around us. I never had. The result is that I took a lot of things for granted.

Now things are different. I've toured their facilities, and I've seen them practice their trade. These people are the people who make a bicycle more than just possible. They make it beautiful.

I look forward to getting up into the saddle of this bicycle more than any before. When I do, and ride away from home for the first time with it, I'll look back and see everyone who put their pride and passion into that ride. Miguel, Steve Thompson, and of course, my husband, Rick.

It is amazing how great the frame looks nickel plated. It surpassed my own expectations. Yet there were several points along the line where one oversight or mistake could have resulted in disaster.

Indeed, if a problem occurs, you cannot just sandblast and start over. Reversing the electroplating process is a tricky and expensive process which can irreversibly damage your frame.

However, a little common sense and doing your homework can help ensure that your frame comes out as beautifully as mine.

Keep in mind that chrome or nickel plating is usually applied to steel frames. If your frame is made if other stuff, consult with your plating shop for options.

The key to your successfully plated bicycle is to find someone who knows what they are doing. Two someones, in fact. If you have never had a frame metal-plated before, find someone who has, and then pump them for information. Be sure to get a recommendation, too. It beats throwing darts at the yellow pages.

If you cannot find anyone, check with your local bicycle organizations (something more than a weekend riding club). Also, get onto the internet and check the forums. I suggest i-BOB and bicycleforum. You could also call a few bicycle builders. The custom builders are generally friendly and helpful on such matters.

Of course, there are excellent platers who are little-known to practical bicycling circles. There is an entire artistic bicycle subculture who treat their rides as vehicles of expression. To them, plating a bike is commonplace.

Never go with the first business you find. Get a list of two or three companies and visit them all. When you do, come with a lot of questions and no frame. Get a tour of the shop if you can. It won't be spotless as a microchip factory, because it doesn't need to be. But it should be well organized and reasonably clean. Check out some of their work with special attention to things of similar detail to your frame.

There should be evidence of business, too. I would be hesitant to use a plater with idle lines. You also want to get a vibe--a feel for the place and its people. If you don't feel good about it--no matter how many recommendations they have--go somewhere else. Plating your frame is a big step, and you will want to feel comfortable with the folk who will do it.

If you can, meet with the person who will be handling your frame. Some larger shops have a separate manager for small parts. Ask him or her any questions and express any concerns you have about the process and your frame.

Find out what kind of plating the business does. There are two kinds of chrome plating, and plating companies, out there: industrial/hard chrome plating and decorative chrome plating. Most companies do one or the other.

Hard plating is targeted for industrial purposes where it serves to increase the durability of mechanical parts. As a result, they lay it on thick. Also, hard plating doesn't have that mirror-like quality we all prize in chrome. There are horror stories of folks sending their frame out for plating and having it come back "not very shiny" and with the small details filled-in. There is a chance that the owner had inadvertently dropped their frame off at a hard electroplater.

What we bicyclers understand as chroming or nickel-plating (i.e. the stuff of bumpers and exhaust pipes) is called decorative chroming. It is just as hard as "hard" plating, but much thinner and finished to high reflectivity. Of course, results vary, but a top-notch decorative plater can get that coating supremely thin. So thin that I have heard it said that it weighs less than powder coat. In my case, machinest Steve Thompson was impressed by the work Chrome Nickel Plating had done. The plating was thin enough to leave the tiny, stamped Shimano logo impressed into a cable guide, and the nickel alloy was so hard that it dulled his carbide blades.

When pricing the job, be sure to ask what is included (taxes, fees, etc.), and ask what prep work they expect you to do. Miguel at Chrome Nickel Plating took care of just about everything. Ask after a guarantee-- they may not have one, but than again they just might. If they do, it will probably be the old fashioned type-- their word and a handshake. Some consumer advocates may want you to get something in writing. Good if you can get it, but don't press your luck. Work with them and they are more likely to work with you. If you feel uncomfortable enough to insist on a guarantee in writing, then you best move on to the next plater on your list.

If you choose nickel plating, know that it will tarnish--which takes the form of a dulling white film. Some nickel alloys, Steve Thompson tells me, will also turn grey. By stopping at this stage of the electroplating process, you actually reduce the amount of hazardous waste. Nickel plating has a warm, smoky-gold color. It has the same visible reflectance as chromium, but because of its darker tone, it is perceived as producing less glare.

Because chromium is so hard, chrome plating is the lowest-maintenance of these three finishes. It tarnishes slowly and cleans easily. Chrome plating has a brilliant, highly burnished, cool finish that is often described by owners as "glinting."

If you choose to have your frame copper plated, know that it will tarnish like a penny. Faster and greener, in fact, so a clear coat of paint may be in order. I only know of one copper plated bicycle by reputation and photo. Nice, really.

Once you have selected your plater, go home and prep your frame. Even if they offer to remove parts for you, do it yourself. Remove every piece that you do not want permanently sealed to your frame. The bottom bracket and head set leap immediately to mind. I forgot to remove the seat tube screw, but Miguel must have noticed as it came back nickel plated but loose.

When you hand your frame over, review what exactly will, and will not, be done. Also reiterate what needs to be masked. To be honest, I should have had the forks masked-off at the top of the crown. It would have prevented the excess flash and allowed Steve Thompson to mill the forks more easily.

Unless you absolutely, positively need it, don't ask for super-emergency-rush service. In fact, allow slack in your schedule. Though they may try to accommodate you for the sake of customer service, electroplating is a methodological process and you don't want to upset the workflow. To do so is to increase the chances of an expensive mistake.

When you pick up your frame, inspect it closely. The finish should be smooth, even and shiny all over. Any tiny details should be clearly visible. You should see no flash, or buildup at the transition of the finish and bare steal. Touch the finish. It should feel glass-smooth with no bumps or rough spots.

As a general rule, to maintain nickel plating use the same horse-sense you use with chrome plating. To keep it shiny and fingerprint free, a soft cotton cloth with a bit of nape works well. Spritz a little isopropyl alcohol on the cloth first for grimy fingerprints. My mom used glass cleaner on her chrome appliances, and I use dish soap and water to keep the faucets shiny. Just stay away from caustics, and wipe your frame dry afterwards.

To prevent tarnish from building up too quickly, some recommend a carnauba-based wax to keep a nickel-plated frame from tarnishing. I have heard that waxing can sometimes make the finish hazy. Otherwise it seems like a reasonable thing to do. For tarnish removal, my husband is a fan of Simichrome which is a very low-abrasion metal polish. I'll probably do this as needed, too. One thing for sure is that I will not dote on my frame endlessly. I bought it to ride.

I started wiping down the frame of grease et cetera when I noticed a fine line at the base of the head tube. I looked closer and notice that the chrome had split! With growing discomfort I inspected the entire head tube. Indeed, hairline fractures at the top and bottom, at the headset. I inspected the entire frame and found no other flaws.

I started wiping down the frame of grease et cetera when I noticed a fine line at the base of the head tube. I looked closer and notice that the chrome had split! With growing discomfort I inspected the entire head tube. Indeed, hairline fractures at the top and bottom, at the headset. I inspected the entire frame and found no other flaws.

What had happened? We had hypotheses. Both relate to head tube flexing. First is that the headset was too tight and was forced into the tube, causing it to flex. Second is that the head tube was not perfectly round, again causing it to flex when the headset was installed.

Perhaps the headset should not have been so forced. As many Miyatas of that epoch were cut for JIS instead of the more current ISO sized headsets, and JIS uses smaller cups, that is most likely cause. The need to mill the crown race seat should have tipped us off, but when we queried the shop staff later about this very issue, it turned out they'd never heard of JIS parts. So, if you are building up a used Japanese frame, take measurements, and check them against JIS standards.

This is less likely, but perhaps there is a problem with the plating. Perhaps I should have installed the headset so that the head tube could adjust to it properly before having the frame plated. Perhaps I should have stayed with OEM parts. There are a million possibilities, and I like none of them at all.

The finish is ruined in total. There is no fix and no reasonable solution. I could, if I like, undertake the risky and costly task of having the frame reverse electroplated and then replated, but the inconvenience is untenable for me right now. Yet, to leave the fractures is to invite corrosion.

But there is use for the frame still. First to serve as an example to you, the reader. Any work you have to do to your frame, do it before you plate it. This includes truing the rear triangle, straightening the forks, and aligning the frame. Because the flip side of metal plating's durability is that it is not forgiving of shock. It resists grinding, despises cutting, and fails under acute stress. Buy and fit all your parts in advance. This is especially true of older frames with newer components. As we all know, components that share the same measurements but not the same decade will not necessarily be the same size.

The second use of the frame is for my personal enjoyment. Yes, it is no longer perfect, and the finish's life expectancy has been cut severely short. But the ride will be the same, and it is still beautiful; it will still be a lot of fun.

What I plan to do is seal the worst of the splits with a resin. This will prevent rusting and painful cuts should I run my hand over it. The others I will leave until they worsen. You can be sure that I will wax those areas much more often than the rest of the frame.

Am I disappointed? Sure. I didn't even get to ride it before it was damaged. Yet I am endlessly enamored of it, and I know that it will faithfully carry me for many miles and on many adventures.

Author's Note: It won't be a full-on forensic investigation, but you bet I will look into the cause of the damage. I'll write as I know more.

This chapter is the account of that investigation and how things have transpired since. Instead of holding this back until everything is done, I am asking the publisher, Rick, to release it now and let me add to it as things progress. This way we can discover things together.

October 8, 2006

So, yesterday we took the bike into the shop where the headset was installed. Beyond learning why the finish split, Rick wanted to take the extra precaution of having the headset pulled and the head tube inspected for cracks. Chances were that it was going to be fine. After all, no one would force in a headset if it was so ill fitting as to risk damaging the frame.

Yet, Rick peered into the tube and, lo and behold, a hairline fractures was evident. The shop's proprietor disagreed, seeing no damage. Instead, he recommended a second opinion and sent us to Victor Larrabee, a former frame builder, who kept a shop in West Los Angeles.

Mr. Larrabee took a magnifying glass to the controversial spot and confirmed the worst. A thumbnail shaped hairline fracture was clearly evident. He put things into perspective. "You can still ride it. I just wouldn't take it very far." He went on to explained that it would probably not suffer from catastrophic failure. The steering would just become increasingly sloppy over time.

Tentatively, I mentioned touring, the frame's intended use. "No, I wouldn't do that," was his frank reply. "Believe me, any thing that can go wrong, will go wrong."

Frankly, I didn't feel much at that moment. Even as we loaded the frame back into the car and drove back to the bike shop I didn't feel much emotion. I was having trouble getting my mind around what had suddenly transpired. Just a few hours ago I was on the verge of "riding into the sunset." Now I had a cracked frame and I never even got into the pedals.

For six months I enjoyed learning about my frame and, in essence, helped it grow towards being a beautiful and unique bicycle. Working so closely with it, I knew the landscape of its surface like the back of my hand. The tiniest blemish was familiar to me and was a joy to discover. My frame even had a name: "Vivian." "Vivian, My Imaginary Friend." A harkening back to simpler times of childhood pleasures and infinite adventures of imagination.

Now it was gone. I looked back at the frame as we drove, watching it rock slightly as we went. I looked forward again quickly and watched the road. It couldn't be gone. Not so soon!

Returning to the bike shop I wandered around the store, away from the repair side, as Rick spoke with the shop's owner. Forever, it seemed. One of the mechanics, whom I had bumped into at the Santa Monica Critical Mass ride the night before, chatted with me amiably. He had heard what had happened, but we avoided the topic.

Finally Rick called me over. "Let's go," he said. Another mechanic carefully wrapped up the Chris King headset and laid it on the counter before me. The gesture reminded me of someone handing over the personal belongings of a dearly departed.

I said good bye to the staff, except for the shop's owner who had disappeared, got back into the car, and we drove home.

That evening, I finally had enough courage to ask Rick to show me the damage. He lifted the frame into the light and showed me where to look. Sure enough, a U-shaped crack at the top, extending down into the cup seat, and shaped like a thumb nail.

The cause was not clear-cut. Odds were that the headset, sized to ISO standards, was just too big for the head tube, sized to JIS standards. Forcing the installation probably cracked the tube. This also explains the location of the damage to the plating, which is all over the top and bottom of the head tube and nowhere else.

Rick had not heard of JIS headsets before, having only learned of them in discussions about the damaged finish with members of the iBOB list. When he mentioned it to the bike shop owner and the chief mechanic, they only shrugged. They had never heard of JIS either. Rick marveled at this admission. It seemed inconceivable that they would not have known. The shop has been around and selling Japanese frames for over two decades. In all those years how could they manage to remain ignorant about the different standards? If the damage was caused by the installation, it was now no wonder.

Odds were not to deter the shop's owner. Besides denying there was a crack in the steel under the cracked plating in the first place, he then suggested that the damage was caused by improper preparation prior to plating. He then said that it was the risk one takes when installing a headset. Lastly, he suggested that the crack was there when we bought it. For twenty years Rick has been going to this shop, and in that time the two men have developed a casual but reliable friendship. The bike I ride today, an excellent performer, was bought on his recommendation years ago. So we are a little surprised, even disconcerted, by his current behavior.

His last excuse is the only one that has even the possibility of being correct. But only by the thinnest margin. Because Rick is shamelessly thorough when it comes to evaluating a newly adopted frame, and his eye is sharp. He inspected the frame, in particular the areas where components were to be installed, many times over the months and he never found any evidence of such a crack. Especially not a crack so visible even to my eye. Yet, the possibility exists, however remote. Maybe it was there all along. Maybe he could have missed it after all these months.

Because twenty years of solid service and friendship must count for something, and because in the world of matter and machinery many mysterious things can and do happen, I conclude that we will never know how the crack came to be. I have proclaimed the matter spilt milk, and the blame game a waste of energy.

I have had some very nice offers. First, upon subtle pressure from Rick, the owner of the bike shop in question said that he would see if he could find a replacement frame for me. Frankly, I'm not holding my breath, but perhaps he sees value in keeping a 20-year customer. Also, Rick wrote the eBay seller from whom we bought the frame . He had read my previous story and is sorry about what has now happened. He said he would check his "stash" for a similar frame. Finally, Matt, of Kogswell, said he, too, would keep an eye out for a replacement.

Still, my heart is sore, like my legs after a long ride. And I can't say good bye.

For basic technical information on plating see Finishing.com.

A few weeks ago I received an email from a reader, Gary P, who sent his sympathies, encouragement, and an interesting idea. (Let me add that I have received emails, both sympathetic and technically helpful, from readers from all over. Thanks, to each of you. You all rock.)

A few weeks ago I received an email from a reader, Gary P, who sent his sympathies, encouragement, and an interesting idea. (Let me add that I have received emails, both sympathetic and technically helpful, from readers from all over. Thanks, to each of you. You all rock.)

Gary wrote, "Ask Steve Thompson if he would turn for you two 17-4 alloy stainless steel rings that will be .002 in. smaller on the inside than the head tube lugs are in their outside diameter. To install them, heat them up and they will expand, then fit them in place on your frame over the top and bottom of your head tube. They will shrink when they cool and fit as tight as a drum."

Meanwhile, Steve Thompson called. He, too, had heard about Vivian's misfortune and insisted that we let him try to help. So we scheduled some time and I arrived with Vivian (the bicycle), Rick, Gary's good idea, and some hope.

At this point my determination to find the root cause, to point a finger at someone or something is completely gone. Answering a question is one thing, but playing the blame game is never productive.

For an hour we discussed Vivian's condition and reviewed our options. Several short, hairline cracks were evident at the head tube top, but to our surprise, they weren't all in the frame. At Steve's very close inspection he found that the inside of the tube was at least partially plated. This wasn't evident by merely peering into the dim tube. Un-burnished, the plating inside the dim pipe looked like clean metal. This means that some of these cracks were in the plating, not the frame. This also underscores my earlier advice to either mask the frame yourself, or review the masking needs with your plater. Every crack in the plating is another way for corrosion to get in.

Still, the question of what to do remained. Gary's idea agreed with Steve quite a bit, who deemed it "very good." But it turned out that Vivian's head tube lugs had either flared, or were designed to flare, at the openings, making it impossible to fit rings small enough for a tight press. Welding the tube was also out of the question. The trouble of stripping, welding, grinding, and re-plating was just too arduous and costly with no guarantee of keeping any kind of esthetic integrity.

Still, the question of what to do remained. Gary's idea agreed with Steve quite a bit, who deemed it "very good." But it turned out that Vivian's head tube lugs had either flared, or were designed to flare, at the openings, making it impossible to fit rings small enough for a tight press. Welding the tube was also out of the question. The trouble of stripping, welding, grinding, and re-plating was just too arduous and costly with no guarantee of keeping any kind of esthetic integrity.

Since we couldn't strengthen the broken tube, we had to turn to the headset, and the source of the cracking: outward pressure on the tube. Steve decided to relieve some of the pressure by taking 1 to 2 thousands of an inch off the headset at the press fits, and using Loctite Bearing Retainer Fluid to improve the hold. The fit would be just tight enough to hold and no more. This will relieve the stress on the tube, preventing (somewhat) the cracks from getting worse. Though it meant that the headset would never be used on another bicycle, and that replacing it down the line would be difficult, we felt that the solution would extend Vivian's life to make it worthwhile. Not a perfect solution, but the best one under the circumstance. But, if everything went well, she could be built-up that evening.

Everything went smoothly, and two hours later we were back home with Vivian in the living room, looking out the window at a better future.

Vivian and I went out to take a few pictures together a few weeks ago. We also went on a dinner ride with Rick. What a comfortable riding bicycle, and absolutely silent. Nearly as quiet as Rick's fixie.

Vivian and I went out to take a few pictures together a few weeks ago. We also went on a dinner ride with Rick. What a comfortable riding bicycle, and absolutely silent. Nearly as quiet as Rick's fixie.

The dinner ride, barely a mile long, was her true maiden voyage. Our bikes whispered through the darkened streets and by the shuttered homes of a Hasidic neighborhood, and I marveled at the smoothness of the ride, and the comfort.

Vivian is also stable and loves straightaways. She doesn't like traffic, and negotiating the busier streets takes a firm hand (whereas my old Mule loves to corner and weaves through traffic like a chain through its idler gears). And Vivian can sprint! She may not be young, but she's a filly true.

This past Tuesday I took her to work. A bike-train-bike commute that translated into a 20 mile ride. Together with a recreational 30 mile beach ride and a few other jaunts, in totals about 75 miles of near-perfect performance.

I have compiled a few photos and a parts list for those who are interested. (About 50% of the parts are new.) My favorite parts include 1) the Chris King pink headset, which is awesome, 2) the Avocet slicks, which ride smooth and stick fast, 3) the ProMax/Kogswell 537 brakes which work, and look great, and 4) the Allara yellow toe straps.

The only outright dud component is the creaky, worn-out saddle, which was free and beats riding without one.

- Bars: Nitto Randonneur

- Stem: Nitto Technomic

- Brake Levers: Shimano DuraAce

- Shifters: Shimano Ultegra bar-Cons

- Headset: Chris King [CSR] pink

- Saddle: Selle Itallia MTS

- Seat post: nameless

- Cable guides: Suntour vintage

- Brakes: long reach ProMax/Kogswell 537 with Koolstop pads

- Freewheel: 7-speed Shimano 11/28

- Rear Derailleur: Shimano Alivio

- Crank: Sugino XD

- Chainrings: 46/36/26

- Front Derailleur: Suntour XC Ltd.

- Bottom bracket: Shimano UN73

- Pedals: MKS GR9

- Toe clips: KTT stainless steel

- Clip straps: Allara yellow leather.

- Rims: SunRims M13II

- Front Hub: Suntour sealed bearing

- Rear Hub: Phil Wood freewheel hub, 126mm

- Tires: 28mm Avocet Fastgrip K Duo Carbon-12 slicks

Text & photos by Gina Morey